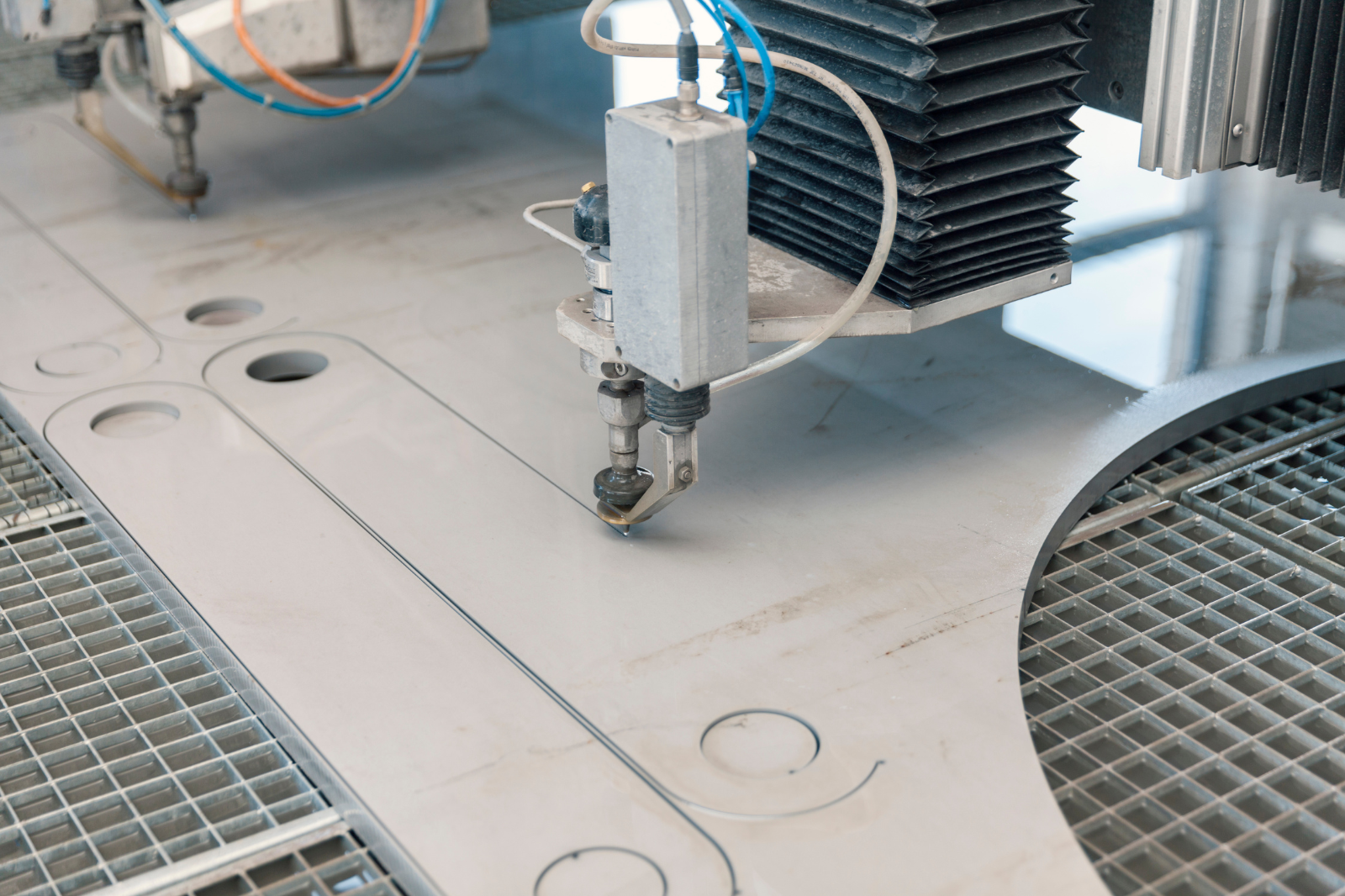

CUT Metal

From aluminium to tool steel and titanium, Suraro Enterprises delivers high-precision waterjet cutting solutions to enhance your prototyping and production processes. Our state-of-the-art waterjet technology allows you to produce in-house with greater speed and accuracy no more outsourcing delays. Gain faster cycle times while maintaining complete control over your quality and workflow.

Glass

At Suraro Enterprises, we offer industry-leading glass cutting services using cutting-edge waterjet technology designed for precision and delicacy. Glass, being a brittle and sensitive material, requires a non-invasive cutting approach and our cold-cutting process eliminates the risk of thermal stress, cracking, or chipping. Whether you need intricate patterns for interior décor, complex shapes for architectural elements, or precision cuts for industrial glass components, our waterjet system delivers unmatched accuracy with smooth, polished edges every time. We handle a wide range of glass types, including float glass, laminated glass, and specialty coated surfaces, all while maintaining the integrity and clarity of the material. With fast turnaround times, custom cutting capabilities, and a focus on quality control, Suraro Enterprises is your trusted partner for high-performance glass cutting tailored to your exact needs.

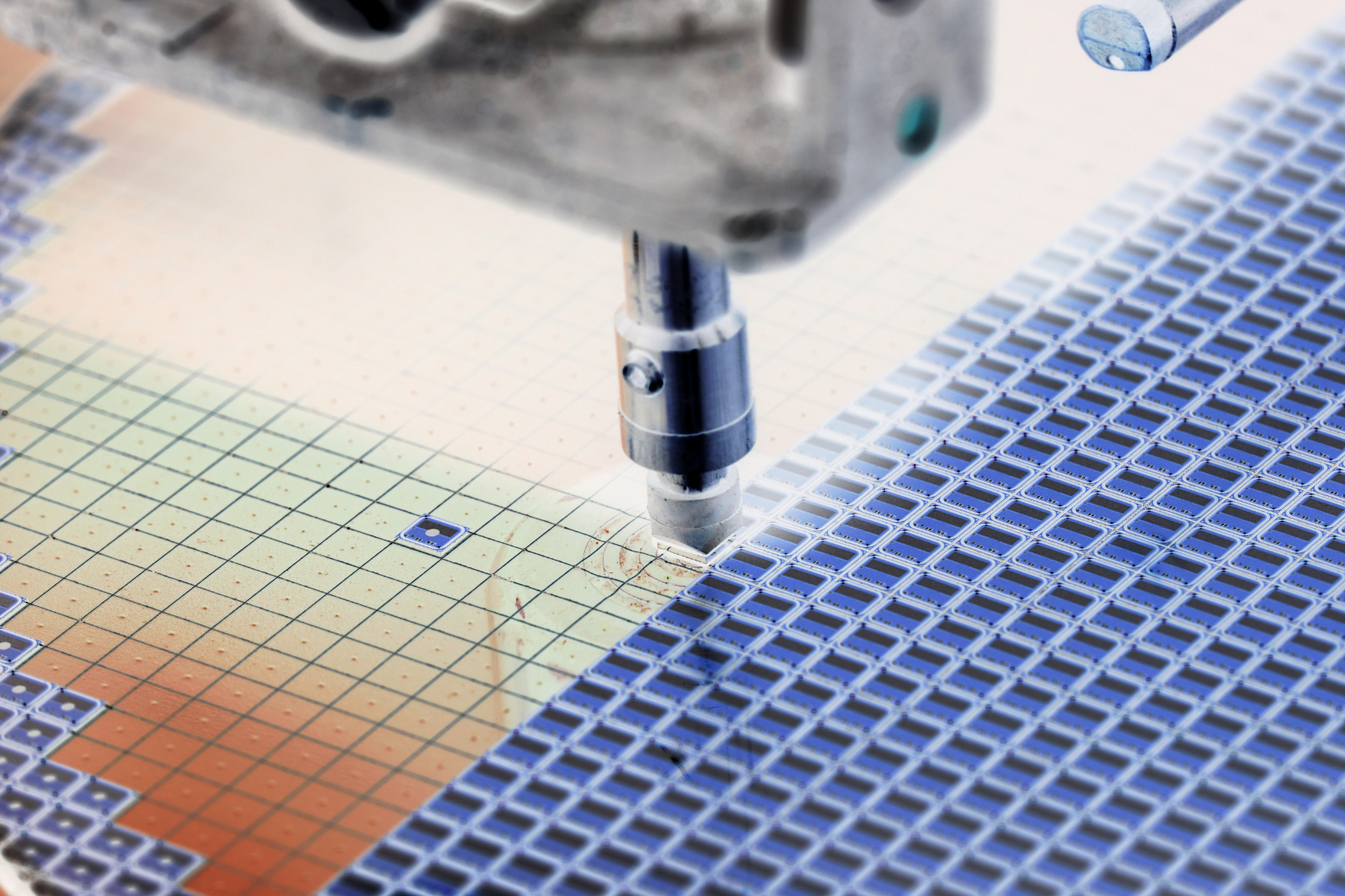

Composites

Cutting composite materials requires more than just precision—it demands a process that preserves the integrity of complex, layered structures. At Suraro Enterprises, we specialize in non-destructive, high-precision cutting of composites such as carbon fiber, fiberglass, Kevlar, and hybrid laminates. Our state-of-the-art waterjet technology delivers clean, accurate cuts without causing delamination, fraying, or heat distortion, making it the ideal solution for industries like aerospace, defense, automotive, and marine manufacturing. Whether you’re fabricating lightweight structural parts or intricate prototypes, our in-house capabilities ensure your components are cut with exacting detail, minimal waste, and maximum reliability.

Foam

Suraro Enterprises provides high-precision foam cutting solutions using advanced waterjet technology, delivering clean, accurate results without compressing, burning, or damaging the material. Whether you’re creating custom packaging, insulation panels, or intricate foam components, our process ensures smooth edges, minimal waste, and consistent quality. From small batches to large production runs, we offer fast turnaround and full control to meet your exact specifications across a wide range of foam types.

Rubber

At Suraro Enterprises, we specialize in high-precision rubber cutting using state-of-the-art waterjet technology, perfectly suited for materials that demand clean, accurate shaping without damage. Rubber being soft, flexible, and prone to distortion under heat requires a cold-cutting process that eliminates burning, fraying, or melting. Our waterjet systems cut through a wide range of rubber types, including natural rubber, EPDM, neoprene, silicone, and industrial-grade blends, with unmatched precision. This ensures that every gasket, seal, or custom component we produce meets exact specifications, regardless of complexity or scale. Whether for automotive, industrial, medical, or commercial use, Suraro Enterprises guarantees consistency, speed, and quality with every cut reducing waste and improving production efficiency.

Gas Cut

Suraro Enterprises provides professional gas cutting services designed for heavy-duty applications involving thick mild steel. Using high-temperature flames and precision-controlled oxygen jets, we deliver clean, accurate cuts ideal for fabrication, construction, and industrial repair work. Our experienced team ensures consistent quality, minimal material waste, and fast turnaround—making gas cutting a reliable and cost-effective solution for large-scale metal processing needs.

Silicone

At Suraro Enterprises, we specialize in cutting silicone with unmatched precision and care. Silicone is a flexible, durable material widely used across industries such as medical, automotive, electronics, and manufacturing. However, its softness and elasticity make it challenging to cut cleanly using traditional methods. That’s where our advanced waterjet cutting technology comes in. Our process uses a cold, high-pressure water stream to produce clean, accurate cuts without heat damage, deformation, or fraying preserving the integrity and performance of the silicone.

Fused Glass

At Suraro Enterprises, we offer expert fused glass cutting using advanced waterjet technology that ensures clean, chip-free edges without the risk of cracks or thermal damage. Our cold-cutting process is ideal for preserving the integrity and beauty of fused glass, making it perfect for decorative pieces, architectural installations, and artistic applications. With a focus on precision and care, we deliver custom-cut glass components that meet exact specifications helping designers, artists, and manufacturers bring their visions to life with unmatched accuracy and consistency.